Wood takes quite a journey from the verdant forest to the industrial saw. Trees are carefully selected based on a number of qualifications, inspected for maximum yield, cooked to soften the texture and reveal the character, and placed in vats to loosen the cellulose fibers for the slicing process. Along this journey, every step is critical to bringing out the best in every specimen.

Once the logs enter the milling facility, the bark must be removed. Then the raw logs must clear a metal detector inspection to prevent bullets, nails and other metal objects from ruining the blades. Finally, the log is sawn into halves or quarters, known as a flitch.

To ensure the leaves of veneer stay intact when sliced thinly, logs are placed into a steel vat and heated with water to cook them. The temperature and length of cooking depend on the species, and each veneer mill has its own preferences.

Each section of the log, or flitch, must then pass through a final cleaning process to plane the outside of the log, which removes excess bark or irregularities.

Before slicing the flitch into thin veneers, it must be attached to the flitch table, and typically a vacuum is used to secure it.

This is where the magic happens. The flitch is converted into leaves, or sheets of very thin veneer, and the average slicer will produce up to 100 sheets per minute, depending on the type of wood and cut.

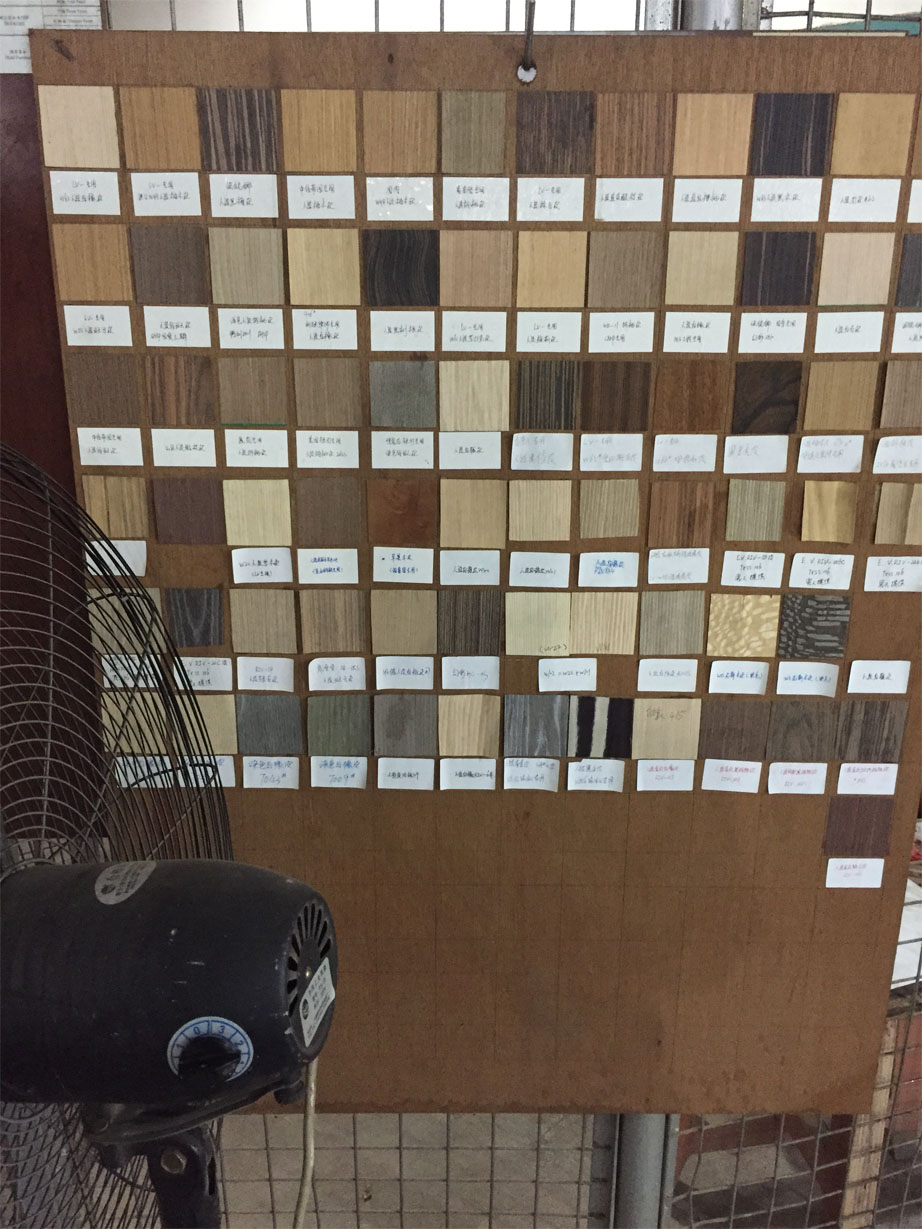

While a plain slice or flat cut is the most recognized type of slicing method for high-quality veneers, there are several ways to cut a log. Each method creates a distinctive look, from putting the growth rings on display to embracing the irregularities present in all wood. The type of slicing method used depends on aesthetic preferences, budget and other factors.

Different types of veneers: